Screening applications are critical in many industries such as construction, agriculture, manufacturing, and even home improvement. The effectiveness of a screening system largely depends on the quality and design of the material used. Custom wire mesh has become an essential choice for enhancing both durability and performance in these applications. This article explores how custom wire mesh contributes to better screening results and why it is a smart investment.

Understanding Custom Wire Mesh

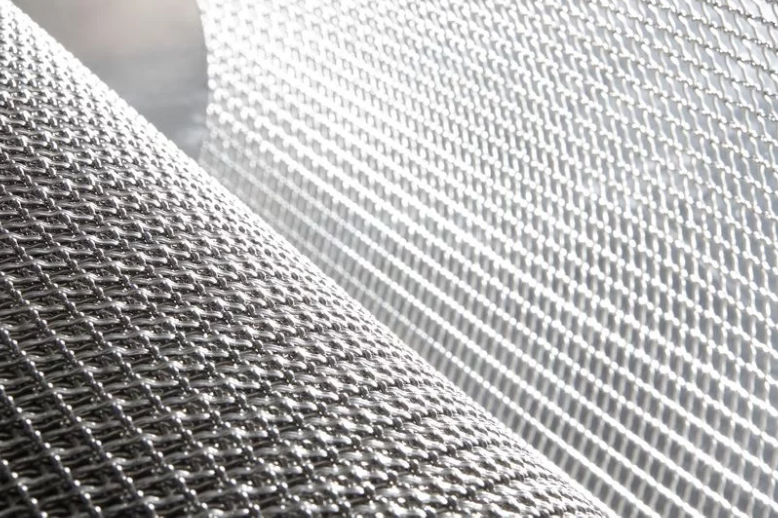

Custom wire mesh refers to a wire mesh product tailored to specific needs and requirements. Unlike standard wire mesh, which comes in fixed sizes and patterns, custom Wire mesh can be designed with precise dimensions, wire thickness, mesh size, and materials to suit particular applications. This flexibility allows users to select the most suitable mesh for their screening tasks, ensuring optimal efficiency and durability.

Durability Through Tailored Material Selection

One of the key advantages of custom wire mesh is the ability to choose the material that best withstands the environmental conditions it will face. For example, stainless steel mesh is ideal for corrosive environments or where hygiene is important, such as food processing or chemical screening. On the other hand, galvanized steel mesh offers strong resistance to rust, making it perfect for outdoor applications exposed to weather.

By selecting the right material and wire gauge, custom wire mesh can endure heavy use without breaking or deforming. This tailored approach extends the lifespan of the mesh, reducing the frequency of replacements and maintenance costs. The enhanced durability also means that the mesh continues to perform consistently over time, supporting reliable screening.

Improved Performance Through Custom Design

Performance in screening applications is often measured by how well the mesh separates or filters materials. Standard meshes may not fit all screening needs because different particles or objects require different mesh sizes or shapes for efficient sorting.

Custom wire mesh enables precise control over mesh size and pattern. Whether the task requires filtering out very fine particles or allowing larger objects to pass through, a custom design ensures the mesh meets these needs exactly. This leads to higher accuracy in sorting and less chance of clogging or blockages.

Additionally, custom meshes can be designed to optimize airflow, liquid drainage, or light penetration, depending on the application. These design features enhance overall operational efficiency, which is particularly important in industrial or agricultural settings where productivity matters.

Adaptability for Diverse Applications

Another benefit of custom wire mesh is its adaptability. Different industries and projects have unique requirements, and custom mesh can be tailored to meet these specific demands. For example, in construction, custom wire mesh might be designed to reinforce concrete or provide security fencing with specific thickness and strength.

In agricultural use, it can serve as protective screens for crops or livestock, designed to withstand impact and harsh weather conditions. In manufacturing, it might be used for precise filtration of powders or liquids, requiring very fine and durable mesh patterns.

This adaptability makes custom wire mesh a versatile solution, capable of enhancing performance in a wide range of screening applications, regardless of complexity or scale.

Cost Efficiency Over Time

Although custom wire mesh might have a higher upfront cost compared to standard options, its long-term benefits often justify the investment. Because it is designed specifically for the task, it reduces downtime caused by mesh failure or inefficient screening.

The increased durability means fewer replacements and less maintenance, saving money over the lifespan of the mesh. Additionally, better screening performance can lead to higher quality outputs and less waste, contributing to overall operational savings.

Choosing a custom wire mesh also means less risk of damage to other equipment due to improper screening materials, further protecting your investment.

Conclusion

Custom wire mesh plays a vital role in enhancing the durability and performance of screening applications. Its tailored material choice, precise design, and adaptability to specific needs make it a superior option compared to standard mesh products. While the initial cost may be higher, the long-term benefits in terms of durability, efficiency, and cost savings are significant.

For anyone involved in industries that rely on screening, investing in a custom wire mesh is a smart decision that can improve results and ensure lasting performance. Whether used in construction, agriculture, manufacturing, or other fields, custom wire mesh is a dependable solution to meet modern screening challenges effectively.